What is MES?

Manufacturing Execution Systems

Manufacturing Execution Systems

A manufacturing execution system is an electronic information system that helps the manufacturing process become more efficient. Steps in the manufacturing process are tracked in real time, documented and controlled.

The main goal of MES is to maintain high performance and improve production. MES offers a lot of variation in systems to help customize a solution that meets your requirements.

Functions of MES:

Data Collection

Real-time data collection from the complete production lifecycle.

Employee Management

Analyze your employees to find their best qualities to utilize them in the most effective ways.

Product Tracking

Track work-in-progress (WIP) through production in intermediate steps.

Performance Analysis

Find out what can be optimized in your process and become more efficient.

Quality Assurance

Optimize quality and reduce warranty claims by capturing all quality data.

Maintenance Management and Support

Schedule and plan for preventive maintenance for production tools.

Benefits of a manufacturing execution system:

Reduces WIP

Reduces labor costs

Improves product quality

Improves customer service/customer satisfaction

Improves supply chain visibility

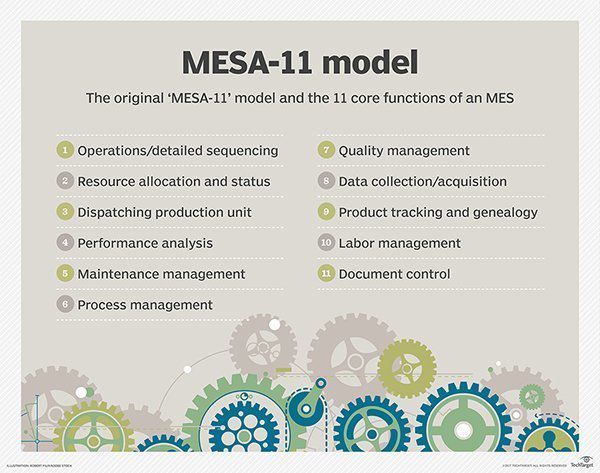

The Manufacturing Enterprise Solutions Association (MESA) International created the first MES Model, pictured to the right.

Manufacturing organizations managed and automated their accounts with software applications in the 1970s. Those apps were improved in order to provide the standard inventory management features. After those apps were improved and standardized, the MRP (Material Requirements Planning) systems came into play in the late 1970s/early 1980s.

MES began as simple data collection and turned into a more modern software.

PHOTO FROM: https://searcherp.techtarget.com/definition/manufacturing-execution-system-MES

Avoid communication problems and production delays.

Check out OdooGap's Manufacturing Solutions.